- Dampers can be produced in any size diameter, length x width, or face-to-face.

- Carbon steel or stainless steel are standard for body and blade construction, but any weldable alloy can be used. FRP (Fiberglass Reinforced Plastic) can also be used for body and blade construction.

- Design pressures are normally up to 60" wc but higher design pressure dampers are available.

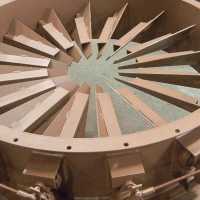

- Dampers are available with several different types of seating configurations: scissor seat, metal-to-metal seat, step seat, resilient seat, tadpole seat, or teflon o-ring seat.

- Castable or blanket refractory is utilized for higher temperature applications; up to 2200ºF.

- Solid plate blade design is standard. For higher pressures, dampers are furnished with reinforcing blade stiffeners. Air foil blades are also available.

- Teflon bearing and packing are standard but other types of bearing and packing materials are available.

- Dampers can be furnished with a variety of actuating and control mechanisms.

Manufacturer of dynamic and progressive valves & dampers