Barneby & Sutcliff / MegTec

- Size: 48” Valve w/ Teflon o-ring seat design

- Problem: Recycle VOCs and extract byproducts.

- Require tight ANSI Class VI shut off

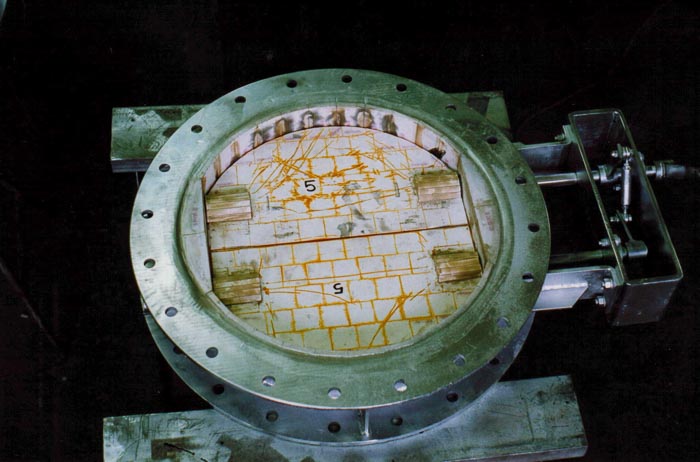

Foster Wheeler

- Size: 24” Dual blade ceramic lined damper

- Problem: Abrasive coal and ash at high velocity and high temperature.

Kodak Rochester, N.Y.

- Size: 44” Refractory lined damper w/cast step seat

- Problem: Extreme service temperature of 2200 deg.F. for a chemical waste incinerator.

Soliant LLC / Akzo Nobel

- Size: 42” Elliptical damper

- Problem: Needed a cross-over damper in between two ducts with limited space.

Power Plant Columbia

- Size: 120” x 120” Flap diverter

- Problem: Divert turbine exhaust from the turbine to stack or boiler if needed.

Formosa Plastics

- Size: 28” Titanium dampers w/ Viton seat for ANSI Class VI shut-off

- Problem: Very corrosive service conditions: condensation of hydrochloric acid vapors.

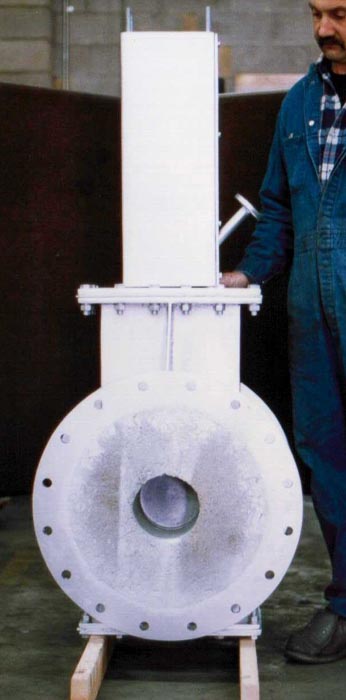

Wheelabrator Frackville

- Size: 6” Refractory lined slidegate/ knifegate

- Problem: Extreme service of 2200 deg. F. for Cogeneration plant burning coal/rock (culm)