Elastomer Seated Valves

- Elastomers include Teflon*, Viton*, Neoprene, Buna, EPT, and other commercially available elastomers.

- Designs for low pressure gas and liquid handling systems means lower operating torques which reduces the cost of actuation packages.

- Carbon steel and stainless steel are standard construction but any weldable alloy can be used.

- Can be constructed for food grade service.

- AWWA type valves also available to handle higher pressures.

Light Duty Dampers

Advanced Valve Designs' LD style dampers are intended for use in HVAC systems and low pressure (<10" wc) industrial applications.

http://www.advancedvalve.com/images/light-duty-damper.jpg

- These valves should be used in clean gas systems where particulate matter is not a concern.

- These dampers offer light weight, economy and durability in low pressure systems.

- Standard material is carbon steel but are available in a wide variety of alloy materials (304 S/S, 316 S/S aluminum, etc.).

Fabricated Dampers

- Dampers can be produced in any size diameter, length x width, or face-to-face.

- Carbon steel or stainless steel are standard for body and blade construction, but any weldable alloy can be used. FRP (Fiberglass Reinforced Plastic) can also be used for body and blade construction.

- Design pressures are normally up to 60" wc but higher design pressure dampers are available.

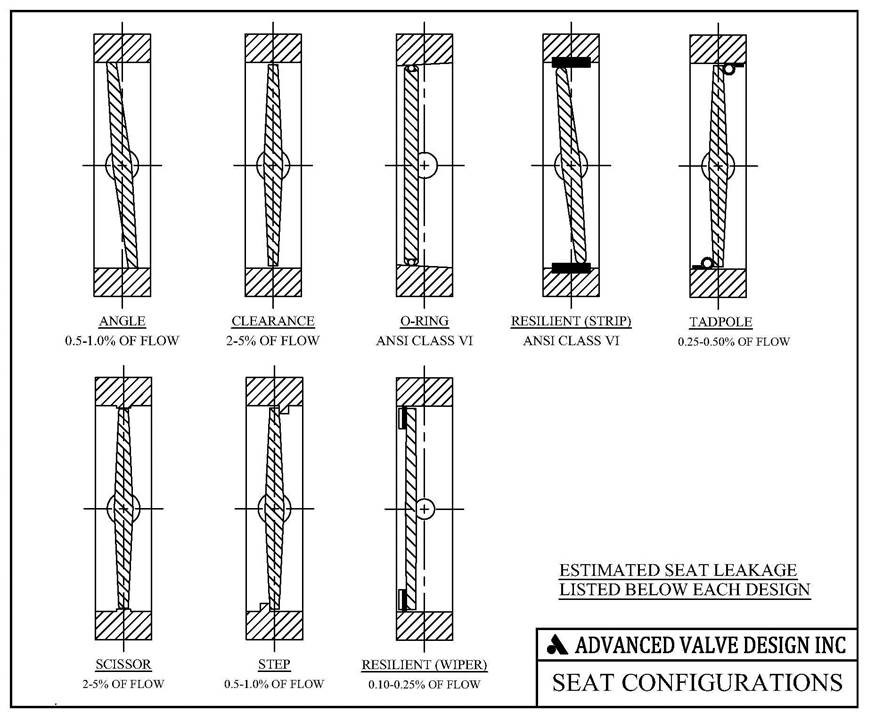

- Dampers are available with several different types of seating configurations: scissor seat, metal-to-metal seat, step seat, resilient seat, tadpole seat, or teflon o-ring seat.

- Castable or blanket refractory is utilized for higher temperature applications; up to 2200ºF.

- Solid plate blade design is standard. For higher pressures, dampers are furnished with reinforcing blade stiffeners. Air foil blades are also available.

- Teflon bearing and packing are standard but other types of bearing and packing materials are available.

- Dampers can be furnished with a variety of actuating and control mechanisms.

Special Dampers

Dampers designed for temperature to 2000ºF+ either internally insulated (refractory lined) or all alloy construction for external insulation.

http://www.advancedvalve.com/images/special-damper.jpg

- Various seat styles available: tadpole, clearance, scissors, and step (machined or non machined).

- Alloys to suit your needs: inconel, hastalloy, micro alloys, 310 S/S, 330 S/S and other commercially available alloys.

- Refractory lined dampers available with floating metallic liners to eliminate the erosive conditions found in many refractory lined dampers.

- Field proven designs (references upon request).

Standard Butterfly Valves

Our standard butterfly valves can be used for air, gas, and water applications where absolute "tight" shut-off is not required. These low pressure, metal seated valves are furnished with a cast iron body and disc. Type 304 stainless steel shafts, teflon bearing, teflon packing, steel packing gland and a steel pipe plug.

http://www.advancedvalve.com/images/standard-butterfly-valve.jpg

Our standard valves are:

- Available in wafer or lug.

- Suitable for 25 psi differential pressure through the 12" size and 15 psi differential in sizes 14" and above.

- Designed to fit between ANSI 125/150 LB. or RPM flanges.

- Able to handle temperature from -20ºF to +450ºF.

All standard valves are available in various seat configurations to meet specific applications and service conditions. Some of the available seat designs would be: angle seat, step seat, scissor seat, clearance seat, resilient seat, o-ring seat, and tadpole seat.

(Note: These valves can also be furnished for 50 psi differential pressure with the same trim options that are available for the low pressure series.)

Valve Seat Configurations